Measuring Better with MSENSE DGA

How Taiwan Power Company (TPC) uses MSENSE DGA sensors from MESSKO to make its transformers safer.

Kent Yang, Department Manager at Fortune Electric, a manufacturer of power and distribution transformers in Taiwan which also helps TPC to equip its transformers, explains: “The sensor displays quickly started breaking, false alarms and other malfunctions were happening every day, and maintenance costs sky-rocketed.” In short, the “smoke gas detectors” were useless.

MSENSE; MORE CERTAINTY

As the errors were piling up, TPC attended a product presentation where they learned about the new sensor that MESSKO had launched on the market, MSENSE DGA 3. This sensor detects the hydrogen content (which indi cates thermal and electrical faults in the windings), the carbon monoxide content (which is an indicator for the wear levels of the insulating paper), and the moisture content in the oil. This makes it possible to draw conclusions about the oil quality. And that is exactly what TPC needed.

TPC was now able to detect changes in individual gases much more accurately. Furthermore, the software provides TPC with a better understanding of the historic development of the measured values.

Ian Chen, Project manager at Fortune Electric

Because the previously installed sensors had only measured the total dissolved combustible gas (TDCG), thus giving an imprecise picture. And so curiosity had been piqued, the will to change manufacturers was present, and after successful certification by TPC, Fortune Electric could start with the installation. Fortune Electric purchased MSENS DGA from MESSKO and sold the devices to TPC. The responsible project manager at Fortune Electric, Ian Chen, said of the results, “TPC was now able to detect changes in individual gases much more accurately. Furthermore, the software provides TPC with a better understanding of the historic development of the measured values.”

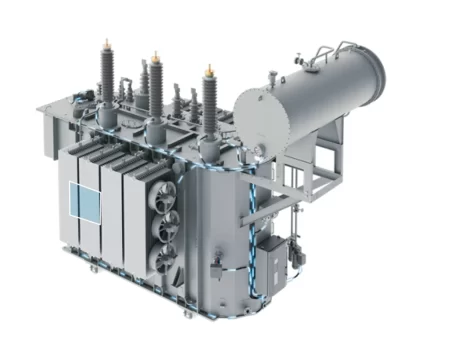

In the meantime, with the help of Fortune Electric, TPC has already equipped 200 transformers with MSENSE DGA 3. Replacing the sensors is extremely simple because it is possible during active operation.

We received excellent support throughout the entire project. Reinhausen helped us and TPC with the configuration and calibration and performed tests. They also trained Fortune Electric and TPC employees

Ian Chen

Source:

User comments