ETOS – The First Open Standard for Digitalizing Power Transformers

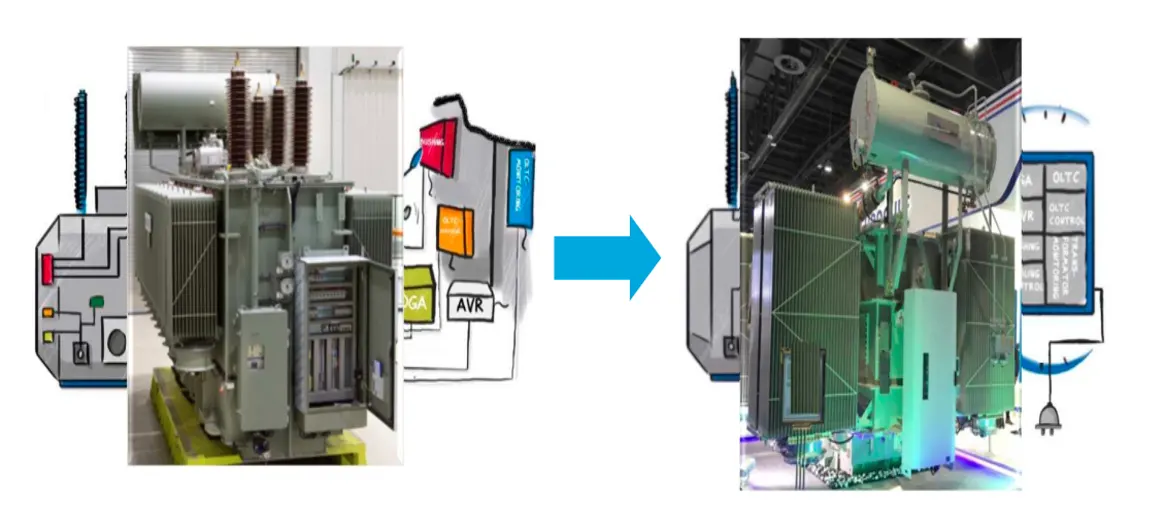

With increasing demands being placed on energy networks and the average age of power transformers rising, intelligent equipment is becoming a must-have. Through ETOS (Embedded Transformer Operating System), Maschinenfabrik Reinhausen (MR) is providing a first – an open, modular system solution for automating power transformers. The system as a whole comprises monitoring and security equipment, sensors, field devices for control, regulation, and monitoring, plus superordinate fleet monitoring – achieving optimized operations management with maximum operational reliability while simultaneously reducing life-cycle costs.

The system as a whole comprises monitoring and security equipment, sensors, field devices for control, regulation, and monitoring, plus superordinate fleet monitoring – achieving optimized operations management with maximum operational reliability while simultaneously reducing life-cycle costs.

One Solution for Everyone

ETOS (Embedded Transformer Operating System) is the practical automation solution for transformers from all manufacturers and of all ages – for either an individual transformer or a whole fleet.

ETOS For Operator

Dispersed generators, volatile voltages, and increased network complexity are just some of the challenges facing network operators. ETOS helps to increase the reliability and resilience of networks and enables more efficient utilization of transformers during operation and maintenance. During the duration of their projects – and at any time afterwards – network operators can benefit from Reinhausen‘s advice and expertise.

“The gradual digitalization of our transformers enables us to evaluate the status of our systems significantly more quickly, more efficiently and, above all, more consistently than before. We now no longer need to travel to the transformers but can access them directly from the control center instead.”

Rúnar Svavar Svavarsson, Technical Manager at Veitur

For Manufacturers

ETOS provides transformer manufacturers with a scalable, individually adjustable system solution that is open for the connection of sensors from any supplier and for the integration on any Scada or cloud systems. So they don’t need to spend time and money developing their own systems. And thanks to its innovative technical functions, no additional costs arise. The collected data even helps manufacturers to optimize their transformers and adapt them more effectively to network conditions and customer requirements in the future.

“The new, open operating system for power transformers allows us to provide our customers with key advantages: We network our transformers with our customers’ digital environments, increase reliability, and maximize flexibility with regard to connecting components and accommodating the requirements of asset management.”

Dr. Jan Declercq, CTO at SGB-SMIT Group

For service providers

Service providers who plan new systems for operators can score points with digital concepts. The mounting of ETOS directly on the transformer allows the captured data to be transferred to the control system via a standardized control-system protocol using a fiber-optic cable. This greatly reduces the amount of wiring needed compared to a conventional connection method and thus significantly lowers costs. Furthermore, the open system allows service providers to integrate their own software in order to adapt processes to customer requirements.

“We are convinced that ETOS and PSIcontrol will allow us to link network management information and equipment information in an intelligent manner. The close partnership between PSI and MR creates new opportunities for optimizing network management which, for example, can significantly reduce network interventions and enable better utilization of the networks.”

Wolfgang Fischer, Business Division Manager at PSI Software AG

source:

User comments