Bushing Monitoring; Keeping an Eye On Voltage

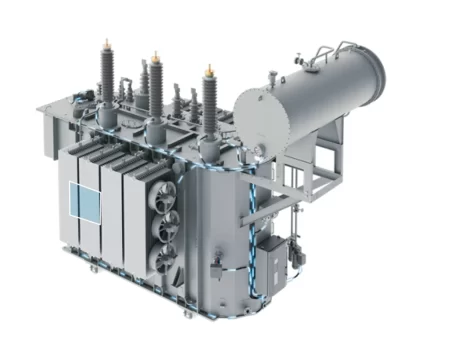

Slovenia has been providing its neighbor, Italy, with power since 2010. The MSENSE BM online bushing monitoring system from MR makes sure that the energy flows reliably.

Bushing Monitoring, Voltage Monitoring

With the help of a simple instruction booklet, the local team installed the MSENSE BM sensors on all 12 oil-impregnated paper bushings (OIP bushings) of the two PSTs on their own. Afterwards, MR commissioning specialist Peter Schelter showed the team how to individually adjust the parameters that were already stored in the system—that was all it took for the electricity to flow between Slovenia and Italy more reliably than ever.

REVISION PLUS RETROFITTING

Although it may sound simple, in reality it was of course much more complicated, as Aleksander Polajner, Head of the High-Voltage Device Department at ELES, describes with a smile: “Revision of phase-shifter transformers is challenging and needs to be planned carefully. These devices control the flow of powerful electrical loads between two countries, and therefore guarantee the safe, reliable, interruption-free transfer or exchange of electricity. In the event of an unplanned failure, in the worst-case scenario, a network outage due to overload could occur.”

MSENSE BM sensors are suitable for monitoring resin-impregnated (RIP) bushings, oil-impregnated (OIP) bushings, or resin-impregnated synthetic (RIS) bushings with voltage levels between 10 kV and 800 kV.

MR designed the MSENSE BM monitoring system for reliable monitoring of high-voltage bushings. An innovative algorithm monitors their capacitance as well as the dissipation factor, and compares any deviations with predetermined limit values. The system immediately notifies higher-level systems if the limit values are exceeded before the transformer sustains any damage.

MR Sales Engineer Service Bastian Niedermeier explains: “Around 17 percent of all transformer failures are caused by defective bushings. For this reason, it is crucial to monitor them in order to ensure the reliability of the system as a whole.”

Bushing Monitoring, SIMPLER AND MORE PRECISE

MSENSE BM bushing monitoring features an innovative concept that uses what is referred to as a double-reference method that monitors the condition of the bushing insulation based on a change in capacitance and the dissipation factor in a three-phase system. Niedermeier: “Since the algorithm permanently monitors all three bushings and compares them with one another, the temperature dependency of other processes, which only measure the voltage at one bushing, is also determined and linked to other measurements, for example the temperature.”

“Our experience in recent years has demonstrated that MR offers excellent support as well as.

Aleksander Polajner, Head of High Voltage Device Department at ELES

The MR system for detection of symmetry of the three-phase network uses the signals of the respective voltage transformers as a reference and checks whether the measurements are valid and whether asymmetries in the network are effectively compensated and eliminated. MR filed a patent for this concept in 2017.

Bushing Monitoring, A RELIABLE PARTNER

In addition to transferring electricity to Italy and vice versa, ELES also operates transmission grids that are connected with Austria and Croatia and they are currently planning a connection to Hungary. This makes ELES part of the Europe-wide multi-regional coupling (MRC) project.

Aleksander Polajner explains: “Our partners count on the reliability of our systems. That is why we are so careful when it comes to choosing the companies we work with. Our current transformers are already equipped with MR system solutions. Our experience in recent years has demonstrated that MR offers excellent support as well as innovative, reliable, safe solutions. By deciding to implement the MSENSE® BM monitoring system going forward, we are already benefiting today from service from a single source.”

Source:

https://onload.reinhausen.com/en/12-2020/keeping-an-eye-on-voltage/

User comments